CHAIN &

FITTINGS

Cautions & Warnings

- General Safety Guidelines for Chain & Attachments

- Temperature & Chain

- General Hook & Latch Guidelines

- Table of Chain Wear

- Chain Sling Safety Checklist

General Safety Guidelines for Chain & Attachments

Peerless Industrial Group, Inc., as a manufacturer of chain, can only control the specifications of our chain products in accordance with industry and governmental standards for chain manufacturing. It would be impossible for any warning to contain all of the possible misapplications associated with the use of Peerless products. Our warnings are intended to identify only those risks which are most common.

The responsibility and understanding of the proper safe use and application of our products, ultimately rest with the end user. We are not responsible for the end user’s assembly in which our chain may be used. Failure of the product can occur due to misapplication, abuse, intentional alteration or improper maintenance. Product failure can result in property damage, personal injury or death.

Working Load Limit (WLL)

The “Working Load Limit” (rated capacity) is the maximum load that shall be applied in direct tension to an undamaged straight length of chain.

Proof Test

The “Proof Test” (manufacturing test force) is a term designating the minimum tensile force which has been applied to a chain under constantly increasing force in direct tension during the manufacturing process. These loads are manufacturing integrity tests and shall not be used as criteria for service or design purposes.

Minimum Breaking Force

The “Minimum Breaking Force” is the minimum force at which the chain during manufacture has been found by testing to break when a constantly increasing force is applied in direct tension. Breaking force values are not guarantees that all chain segments will endure these loads. This test is a manufacturer’s attribute acceptance test and shall not be used as a criteria for service or design purposes.

The Working Load Limits and the associated safety factor of each Peerless product may be affected by wear, misuse, overloading, corrosion, deformation, intentional alteration and other use conditions. Regular inspection must be conducted to determine whether use can be continued at the assigned Working Load Limit, a reduced Working Load Limit or whether the product must be withdrawn from service.

The terms “Working Load Limit”, “Proof Test” and “Minimum Breaking Force” contain no implication of what load the chain will withstand if the chain is used in such conditions of abuse and misuse. Peerless Industrial Group, Inc. accepts no liability for any such abuse or misuse. The Working Load Limit of a sling or assembly must not exceed the lowest Working Load Limit of the components in the sling or assembly. Use only Peerless approved parts as replacements when servicing or repairing original Peerless slings or assemblies.

USE ONLY GRADE 80 OR GRADE 100 ALLOY CHAIN AND ATTACHMENTS FOR OVERHEAD LIFTING. PEERLESS PRODUCTS ARE INTENDED TO BE USED AT OR BELOW THE MAXIMUM WORKING LOAD LIMITS SPECIFIED IN CONSTANTLY INCREASING FORCE APPLICATIONS UNDER DIRECT TENSION OR IN A STRAIGHT LINE PULL. SHOCK LOADING IS PROHIBITED AND SIDE LOADING MUST BE AVOIDED, AS IT EXERTS ADDITIONAL DYNAMIC FORCES OR LOADING WHICH THE PRODUCT IS NOT DESIGNED TO ACCOMMODATE. THE CONDITIONS INVOLVING USE IN CERTAIN ENVIRONMENTAL SITUATIONS SUCH AS UNUSUAL (HIGH OR LOW) TEMPERATURE, CHEMICAL, ETC..., CAN CAUSE CHANGES IN CHAIN PERFORMANCE.

All chains and attachments in this catalog are capable of creating sparks unless otherwise noted. Welding Peerless load support parts or products can be hazardous. Knowledge of materials, heat treatment and welding procedures are necessary for proper welding. CONSULT PEERLESS FOR ADDITIONAL INFORMATION OR QUESTIONS REGARDING THE USE AND APPLICATION OF OUR PRODUCTS. Back to Top

Temperature & Chain

Use of Grade 80 Chain Under Heat Conditions

Effect of Elevated Temperature on the Working Load Limit of Grade 80 Alloy Chain Chains should not be used outside of the -40º F to 400º F (-40º C to 204º C) temperature range without consulting the chain manufacturer. The specific working load limit reductions for Grade 80 chains used at and after exposure to elevated temperatures have been established and are shown below.

| Maximum Temperature of Chain | Reduction of Working Load Limit While At Temperature | Reduction of Working Load Limit After Exposure to Temperature |

| Below 400º | None | None |

| 400º | 10% | None |

| 500º | 15% | None |

| 600º | 20% | 5% |

| 700º | 30% | 10% |

| 800º | 40% | 15% |

| 900º | 50% | 20% |

| 1000º | 60% | 30% |

| Over 1000º | * (see below) | * (see below) |

* OSHA 1910.184 requires all slings exposed to temperatures over 1000º F to be removed from service.

Use of Grade 100 Chain Under Heat Conditions

Effect of Elevated Temperature on the Working Load Limit of Grade 100 Alloy Chain Chains should not be used outside of the -40º F to 400º F (-40º C to 204º C) temperature range without consulting the chain manufacturer. The specific working load limit reductions for Grade 100 chains used at and after exposure to elevated temperatures have been established and are shown below.

| Maximum Temperature of Chain | Reduction of Working Load Limit While At Temperature | Reduction of Working Load Limit After Exposure to Temperature |

| Below 400º | None | None |

| 400º | 15% | None |

| 500º | 25% | 5% |

| 600º | 30% | 10% |

| 700º | 40% | 15% |

| 800º | 50% | 20% |

| 900º | 60% | 30% |

| 1000º | 70% | 35% |

| Over 1000º | * (see below) | * (see below) |

* OSHA 1910.184 requires all slings exposed to temperatures over 1000º F to be removed from service. Back to Top

General Hook & Latch Guidelines

Important Safety Information - Read & Follow

- Always inspect hook and latch before using.

- Never use a latch that is distorted or bent.

- Always make sure spring will force the latch against the tip of the hook.

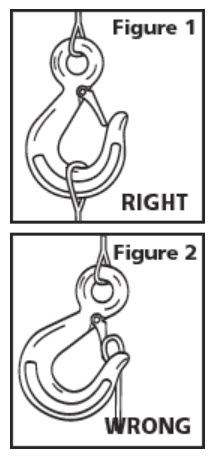

- Always make sure hook supports the load. Do not point load hooks–load should bear on the bowl of hook. The latch must never support the load. (See Figure 1 & 2).

- Latches are intended to retain loose sling of devices under slack conditions.

- Latches are not intended to be an anti-fouling device.

Table of Chain Wear

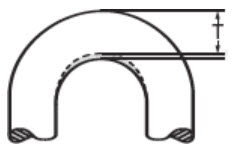

| If chain is worn to less than the minimum allowable thickness (T), remove the chain from service. |  |

||

| Minimum Allowable Chain Link Thickness at Any Point | |||

| Nominal Chain Size | Minimum Thickness (T) | ||

| Inches | mm | Inches | mm |

| 7/32" | 5.5 | 0.189 | 4.80 |

| 9/32” | 7 | 0.239 | 6.07 |

| 5/16" | 8 | 0.273 | 6.93 |

| 3/8” | 10 | 0.342 | 8.69 |

| 1/2” | 13 | 0.443 | 11.26 |

| 5/8” | 16 | 0.546 | 13.87 |

| 3/4” | 20 | 0.687 | 17.45 |

| 7/8” | 22 | 0.750 | 19.05 |

| 1” | 26 | 0.887 | 22.53 |

| 1-1/4” | 32 | 1.091 | 27.71 |

| REFER TO ASME B30.9 | |||

Chain Sling Safety Checklist

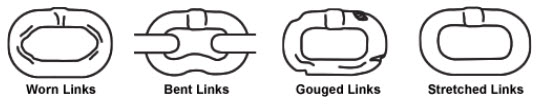

| Check #1 - Inspections Visually examine chain slings daily and before each use. Inspect for removal criteria such as missing or illegible ID Tag, stretched, bent, or worn links, gouges, weld splatter, corrosion, or other damage. All sling attachments including master links, connecting links, and hooks must also be examined for open throats, twists, cracks or distortion, or other damage. |  |

|

|

| Check #2 -Balance Know the load — determine the weight, center of gravity, angle and lift and select the proper size of sling. |  |

| Check #3 - Overload Never overload the sling — check the working load limit on the identification tag. Always consider the effect of Angle of Lift — the tension on each leg of the sling is increased as the angle of lift, from horizontal, decreases. Use the chart in the Peerless Industrial Group, Inc. catalog or in the Peerless Chain Sling User’s Manual for this purpose. |  |

| Check #4 -Knots, Twists & Kinks Make sure chain is not twisted, knotted or kinked before lifting load. Slings should not be shortened with knots, bolts or other make-shift devices. |  |

| Check #5 - Sharp Edges Protect chain slings with padding or protection from damage caused by sharp edges on loads. |  |

| Check #6 - Abrupt Movement Lift and lower loads smoothly. Do not jerk. |  |

| Check #7 - High Temperatures Use alloy chain slings within a temperature range of -40°F (-40°C) and 400°F (204°C). Do not expose slings to temperatures that exceed this range. Refer to the Chain Sling User’s Manual or the Safety Guidelines for capacity reductions when chain is exposed to temperature greater than 400°F. |  |

| Check #8 - Chain Care Store chain slings properly off the floor to protect form corrosion during storage. Do not drag chain slings across the floor. Peerless recommends applying a lubricant or light oil to protect chains from environmental corrosion. |  |