Speedbinders

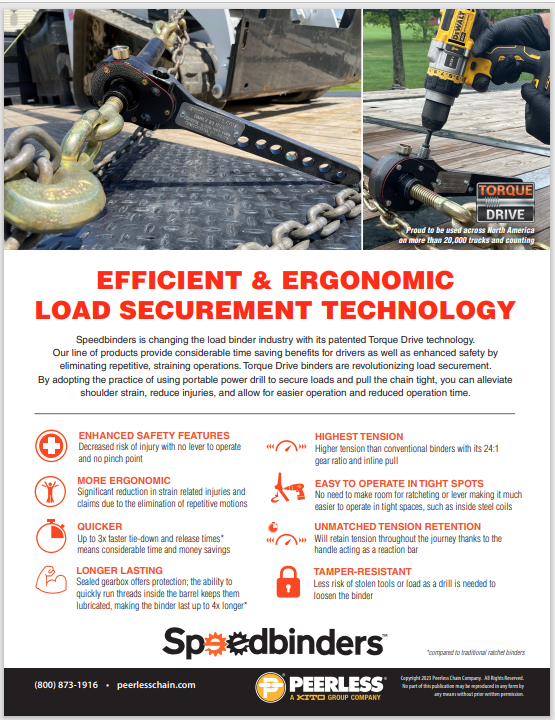

EFFICIENT & ERGONOMIC LOAD SECUREMENT TECHNOLOGY

Speedbinders is changing the load binder industry with its patented Torque Drive technology. Our line of products provide considerable time saving benefits for drivers as well as enhanced safety by eliminating repetitive, straining operations. Torque Drive binders are revolutionizing load securement. By adopting the practice of using portable power drill to secure loads and pull the chain tight, you can alleviate shoulder strain, reduce injuries, and allow for easier operation and reduced operation time.

Frequently Asked Questions

Can I use the handle by hand?

Well, sort of. The handle is designed to be a reaction bar which works best when it is positioned against the floor of the trailer or up against something. It won't rotate the barrel unless it is positioned for full 360 degree rotation. If you must operate the unit by hand, a simple 14mm wrench is all you need. You can use a pair of pliers, vice grips or a socket and ratchet. We actually recommend carrying one on your truck for emergencies.

Are they more expensive than other binders?

Yes they are. But they are so worth it. Companies have found that avoiding just one workman's compensation injury paid for all the binders 10 times over. If you are an owner/operator, how much money would you lose if you had to be down for two weeks due to a torn rotator cuff or tendinitis? The investment is not much more compared to a normal binder. Also, the time and fuel savings really add up. Please try our savings calculator for additional savings.

What about snow and ice?

Torque Drive binders use a sealed gear box utilizing a 24 to 1 gear reduction. This gear set is encased in grease and resistant to outside debris. Normal binders freeze the flipper and paw assembly together making it difficult to break free. We don't have to worry about that due to our encased design. Besides, being drill operated and gear reduced, we power through dirt, snow and ice on your threads rather easily. These binders have been built and tested on the shores of Lake Erie, in the snow belt of the Great Lakes, for years.

Can I use an impact?

We really discourage the use of an impact. We are looking for rotational torque, not "hitting" torque. Impacts can shorten the life of the hex head drive nut.

Can I use the drill I already have?

Yes, you can. Any good 18 volt or 20 volt drill will work. However, to get the maximum performance, speed and tightness from your Torque Drive binders, we recommend the DeWalt dcd991p2. A typical drill has about 320 power watts out. The dcd991p2 has 820! Over 2.5 times the torque. If you use binders on a daily basis, spend the money on this drill or the top of the line Milwaukee Fuel 18. If you use the binders three or four times a month, your average drill will be just fine.

Do I have to use a drill?

Yes, you get to use a power tool! That is the whole point, customers have found this method of operating a chain binder so much easier, faster and safer. We are actually helping truckers who have sore shoulders and elbows repair themselves. In a situation where a drill is unavailable, you can simply us e a 14mm wrench, pliers, ratchet and socket.

What happens if the battery goes dead?

Torque Drive binders are awesome to operate. Once a driver has a few days under his belt, the drill/battery set will be his best friend. He will take care of it. Similar to making sure your chainsaw has fuel before you go out to cut wood. You don't go out there with an empty tank.

For the battery that runs the drill, we recommend last up to 40 full cycles. That will last some truckers two weeks others two days. A simple $4 inverter from Walmart is all you need to keep the second battery charged and ready.

Download the PDF Flyer

Download the PDF Flyer