Vehicles weighing 10,000 Lbs. or more MUST be secured & tied down at a minimum on all 4 corners! Vehicles 10,000 Lbs. or less do not require corner tie-downs.

Calculating the minimum number of Tie-Downs depends on the cargo length, cargo weight and cargo type. The sum of the working load limits from all Tie-Downs must be at least 50% of the weight of the cargo.

Articles 5’ or shorter require 1 Tie-Down. Articles 5’ or shorter and weighing more than 1,100 Lbs. require 2 Tie-Downs. Articles more than 5’, up through 10’ require 2 Tie-Downs. Add an additional Tie-Down for articles more than 10’ and for each additional 10’ or part thereof. (Articles prevented from forward movement by a bulkhead or another load require a Tie-Down for every 10’ and for each 10’ or part thereof.)

Wheeled or tracked vehicles over 10,000 Lbs. require a minimum of 4 Anchor (Direct) Tie-Downs and 4 Tightening Devices – each with a minimum working load limit of 5,000 Lbs. Anchor Tie-Downs are a direct connection between the load and the trailer. All accessory attachments such as booms, shovels and backhoes must be lowered and properly secured – usually with an additional Tie-Down and Tie-Down Device.

Indirect Tie-Downs (not Anchor Tie-Downs) should form a minimum angle of 30 degrees to the trailer floor.

Steel Coils, paper rolls, concrete pipe, dressed lumber, boulders, flattened cars, automobiles, light trucks, vans and containers require special calculations. Always consult FMCSA regarding special applications.

All users must be trained in tie-down selection, use and inspection, cautions to personnel, environmental effects, all applicable standards, regulations & practices. Inspect all chain & load binders before each use. DO NOT USE if any of the following conditions are found: 1) Twisted or bent links, 2) Nicks or gouges, 3) Stretched or elongated links, 4) Excessive wear at any load bearing points, 5) Distorted or damaged hooks or attachment, 6) Unapproved repairs to the chain.

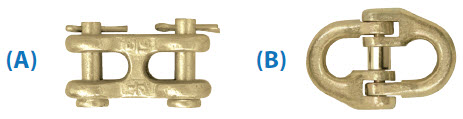

The only approved repair for a tie-down chain is A) TWIN CLEVIS, and/or B) COUPLING LINK of the same grade & size as the chain.

Protect tie-downs from damage when in contact with edges, protrusions or abrasive surfaces.

Never exceed the working load limit (WLL) of the tie-down; taking into account the load, vehicle anchor points and the tie-down configuration and angles.

User must be alert to any and all hazards when securing cargo. Maintain and store tie-downs properly where they are protected from mechanical, chemical and environmental damage.

Tie-Down chain and Load Binder Specifications:

This chart is provided as a guide to meet the basic minimum current in-service requirements in accordance to the FMCSA and the DOT. The following table lists the minimum number of chain assemblies required to secure a load per DOT, CVSA and CCMTA.

PLEASE NOTE: Many factors affect the proper method of cargo securement including the length and type of the cargo to be secured. Refer to the most recent revision of The Department of Transportation (DOT) Regulations Title 49 CFR392~393 in USA or CCMTA – NSC10 in CANADA for more complete requirements regarding the proper methods and number of tie-downs required.

| Chain Grade | Chain Size | Working Load Limit (WLL) | Net weight of cargo to be secured in Lbs. (kg.) | ||||||||||

| 10,000 | 15,000 | 20,000 | 25,000 | 30,000 | 35,000 | 40,000 | 45,000 | 50,000 | |||||

| Chain Grade | Inches | MM | LBS. | KG. | (4,540) | (6,800) | (9,070) | (11,334) | (13,608) | (15,876) | (18,144) | (20,412) | (22,680) |

| ALLOY G100 | 9/32 | 7 | 4,300 | 1,950 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 6 | 6 |

| 5/16 | 8 | 5,700 | 2,650 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 4 | 5 | |

| 3/8 | 10 | 8,800 | 4,000 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | |

| 1/2 | 13 | 15,000 | 6,800 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | |

| 5/8 | 16 | 22,600 | 10,300 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | |

| ALLOY G80 | 9/32 | 7 | 3,500 | 1,570 | 2 | 3 | 3 | 4 | 5 | 5 | 6 | 7 | 8 |

| 5/16 | 8 | 4,500 | 2,000 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | |

| 3/8 | 10 | 7,100 | 3,200 | 1 | 2 | 2 | 2 | 3 | 3 | 3 | 4 | 4 | |

| 1/2 | 13 | 12,000 | 5,400 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 5/8 | 16 | 18,100 | 8,200 | 1 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | |

| TRANSPORT G70 | 1/4 | 7 | 3,150 | 1,430 | 2 | 3 | 4 | 4 | 5 | 6 | 7 | 8 | 8 |

| 5/16 | 8 | 4,700 | 2,130 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | 6 | |

| 3/8 | 10 | 6,600 | 2,990 | 1 | 2 | 2 | 2 | 3 | 3 | 4 | 4 | 4 | |

| 1/2 | 13 | 11,300 | 5,130 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | 2 | 3 | |

| 5/8 | 16 | 15,800 | 7,170 | 1 | 1 | 1 | 1 | 1 | 2 | 2 | 2 | 2 | |

| HIGH TEST G43 | 1/4 | 7 | 2,600 | 1,180 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

| 5/16 | 8 | 3,900 | 1,770 | 2 | 2 | 3 | 4 | 4 | 5 | 6 | 6 | 7 | |

| 3/8 | 10 | 5,400 | 2,450 | 1 | 2 | 2 | 3 | 3 | 4 | 4 | 5 | 5 | |

| 1/2 | 13 | 9,200 | 4,170 | 1 | 1 | 2 | 2 | 2 | 2 | 3 | 3 | 3 | |

CAUTION: This chart is based on each tie-down secured to a trailer point, traversing across or through the load and then secured to another anchor point on the trailer. If used securing the tie-down to the trailer anchor point and attaching it directly to an article of cargo (i.e., a vehicle), the quantity of tie-downs required shall be two times (2x) the quantity listed in the chart above.

PLEASE NOTE: This chart is only to be used as a reference and does not take into account length or special category loads. It serves as a quick reference only. Always consult FMCSA regarding Load Securement Standards before securing.